Workability and related properties of fresh concrete are essential for transport and laying. The properties which determine the quality of the hardened concrete broadly fall into the following three groups :

- Strength.

- Durability.

- Dimensional stability.

Properties of Hardened Concrete:

Characteristic strength, drying shrinkage, creep, modulus of elasticity, permeability and resistance to chemical attack are hardened and time-dependent properties of concrete that may influence structural performance.

We will discuss different properties of hardened concrete below in details.

1. STRENGTH

In simple language, the strength of concrete means the maximum amount of load which it can handle.

In common practice, it is the power of the concrete which is considered its most valuable property.

In fact, high-strength concrete is synonymous with good quality concrete.

The Strength of Concrete can be determined by the compressive strength and tensile strength.

COMPRESSIVE STRENGTH

It may be defined as the maximum compressive load that can be taken by concrete per unit area.

It has been shown that with special care and control, concrete can be made to bear as high loads as 800 kg/sq.cm or even more.

In practice, however, concrete with compressive Strength between 200-500 kg/sq.cm can be easily made on the site for the common type of construction.

The compressive strength is also called the crushing strength, and it is determined by loading axially cube-shaped (or cylindrical shaped, in the USA) specimens made out of the concrete.

The tests are carried out in 3 days, 7 days and 28 days after the casting of the samples.

It has been observed that the compressive (crushing) strength of concrete is influenced by a huge number of factors.

Some of the most important factors are:

i. Type of Cement:

The composition, quality and ‘age‘ of the material which is used in the manufacture of cement that have been stored for the considerable time make concrete of lower strength.

Cement with higher proportions of tri-calcium silicate produce concrete that show higher strengths, at least in earlier stages.

Similarly, finer the particle size of the cement, higher is the ultimate compressive strength.

ii.Nature of Aggregates.

Sand and coarse aggregates form the other two essential components of concrete. A good bond between cement and the aggregates is possible only when the aggregates have sharp edges, clean surfaces, and rough texture.

Smooth and rounded aggregates result in comparatively weak bonds. Similarly, the aggregates used in the concrete making should have in themselves good compressive strength.

For example, if chalk (very soft limestone) is used in making of concrete instead of massive limestone, the resulting concrete will be weak in compressive strength because of the reduced strength of the aggregate.

iii. Water-Cement Ratio.

The compressive strength decreases, in general, with increasing water cement ratio.

Hence, when minimum water has been used just to ensure complete hydration of the cement, the resulting concrete will give maximum compressive strength on proper compaction.

iv. Curing Conditions.

Great importance is attached to proper curing of concrete after it’s laying for obtaining maximum compressive strength.

Incomplete curing and intermittent drying of concrete during the curing period may cause a loss in the compressive strength to the extent of 40 percent or even more.

v. Weather Conditions.

The same concrete placed in different climates -extremely cold and dry hot, may develop different strength values.

The cause is related to incomplete hydration of the cement in the concrete.

vi. Admixtures.

Certain admixtures are added to the concrete at the mixing stage for achieving some specific purposes.

It has been observed that certain admixtures especially calcium chloride, increase the compressive strength.

Some other admixtures (e.g., air entraining agents) however, affect the compressive strength adversely if proper controls are not maintained on the water-cement ratio.

vii. Method of Preparation.

Improper mixing of the concrete and careless transport and placing may result in poor (in strength) quality, despite the best cement and aggregates used in it.

It is the workmanship that determines the quality of the concrete-work in the ultimate analysis. A skilled worker can produce best concrete-mix despite some other deficiencies.

An incompetent labor, however, may spoil the entire work despite being given the best-designed concrete-mix.

The voids left in the concrete on compaction and curing have a profound influence on the strength of the concrete.

Tensile Strength:

Plain concrete (without steel reinforcement) is quite weak in tensile strength which may vary from 1/8th to 1/20th of the ultimate compressive strength.

It is primarily for this reason that steel bars (reinforcement) are introduced into the concrete at the laying stage to get a block of reinforced cement concrete which is very Strong in compression as well as in tension.

In plain concrete, tensile strength depends largely on the same factors as of the compressive strength.

The Tensile strength of concrete becomes a valuable property when it is to be used in road making and runways. It is determined by using indirect methods.

In one of such methods, it is deduced from the flexural strength test. In this test, a beam of concrete is cast in standard dimensions depending upon the nominal size of the aggregate.

Then, the beam is properly cured and tested after 28 days.

In the second indirect method, called the split-cylinder method, the cylinder of specified dimensions is made to fail under tension by applying compressive load across the diameter.

This is termed as Splitting Tensile Strength.

The testing machine is adjusted to distribute the load along the entire, length of the cylinder; From the load at failure, tensile strength is calculated.

2. Durability:

Durability is the second most important quality of hardened concrete. It may be defined as the capacity of hardened concrete to withstand all the forces of deterioration that are likely to act on it, after setting, in a given environment.

Among these forces, the following are more likely to act.

- Frost action.

- Abrasive forces.

- Chemical action.

- Alkali-aggregate reaction.

A brief note on each of these is given below.

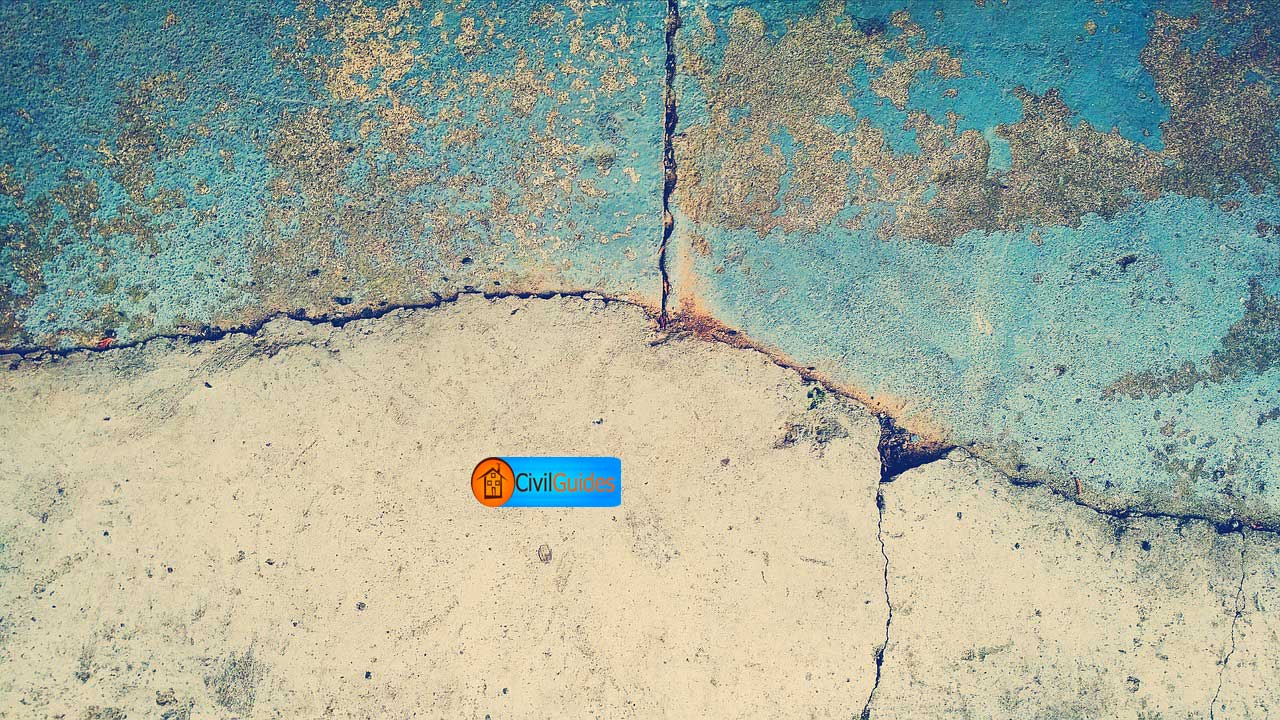

i. Frost Action.

Frost Action is a major cause of deterioration of concrete in Cold Climates. It takes place due to freezing or water within the concrete pores and cavities during extremely cold weather.

Water on freezing expands and exerts pressure on the walls of the pores. This cyclic freezing of water in the pores are responsible for the development of cracks of various nature in the concrete.

To minimize frost actions following measures should be taken.

- In cold weather, the water-cement ratio should be kept as low as possible. This will not allow any extra water to remain within the concrete pores. Hence frost formation will not take place.

- Use good drainage and covering methods for removing any surface water from staying on the concrete during the curing process.

ii. Chemical Attack.

Concrete is liable to attack to various degrees by acids alkalies and salt solutions.

Among the acids, hydrochloric, Sulphuric, nitric and hydrofluoric acid, acetic acid, lactic acid, and formic acid are very harmful to concrete.

The sources of these acids can be from within or outside the environment in which concrete has been used. Thus, hydrochloric acid and sulphuric acid may be present in industrial and domestic sewage.

They will destroy gradually the calcium hydroxide components of concrete used for sewage disposal. Other acids may attack the concrete used in the industrial buildings of acids.

The organic acids are common though in traces, in food processing factories and dairy farms. Concrete used in these buildings will gradually deteriorate from these acids at a fast rate.

iii. Alkali-Aggregate Reaction.

Sodium and potassium hydroxides of cement are capable of reaction with silica.

Since amorphous silica is a common component of many coarse aggregates, such an alkali-aggregate reaction may create harmful effects on cement concrete.

This is because the gel-like silicate structures produced by the above reaction are quite weak and unstable and result in greater expansion.

These may be the cause of frequent cracking in some concrete. For avoiding this reaction, either the percentage of alkalies (K2O and Na20) has to be kept very low in the Portland Cement.

Or a great care has to be taken for selecting aggregates free of amorphous silica-like opal, chert, cristobalite, etc.

3. DIMENSIONAL STABILITY:

CREEP; This defines the behavior of concrete under loads.

It is now well established that concrete is not a truly elastic material. Also, it is not entirely plastic material. When hardened concrete is loaded, it deforms.

- partly as a result of elastic strain (which is recovered on the removal of the load);

- partly as a result of plastic strain (a permanent deformation).

This latter non-elastic time dependent deformation is a typical property of concrete and is commonly referred as CREEP.

Among the various causes of creep, the following may be mentioned:

- Closure of the void-structures of concrete on the application of load;

- Squeezing of water from within the cement gel when the concrete is loaded,

- The flow of cement-water paste, in a viscous state, causing a permanent shrinkage under load;

- Readjustment of aggregates under load.

It is believed that the proportion of mix and the type of cement used in concrete have a profound influence on the rate of creep.

Concrete mixes with higher water-cement ratio will also show higher creep rates.

Creep is thought to be beneficial in some cases and harmful in other cases.

In reinforced concrete, it helps in transferring stresses to the reinforcement and, thereby reducing chances of failure by stress-concentration.

SHRINKAGE:

Hardened Concrete undergoes in three types of shrinkage that are important with respect to its dimensional stability:

- Plastic shrinkage.

- Drying shrinkage.

- Thermal shrinkage.

i. Plastic Shrinkage.

This is the shrinkage that the freshly placed concrete undergoes till it sets completely. It may also be called initial shrinkage.

Such a volumetric change is due to loss of water from the fresh concrete due to evaporation, bleeding, seepage, and soaking by formwork.

Excessive shrinkage at initial stages may develop extensive cracking in the concrete on the setting. Therefore, all precautions should be taken to avoid excessive loss of water due to evaporation.

ii. Drying Shrinkage :

As the concrete has completely set and hardens, some further shrinkage may result because of contraction of gel-structure due to further loss of moisture, or drying (against the term evaporation used in the first type of shrinkage).

This kind of shrinkage is practically an essential and irreversible property of concrete. It has to be met with by careful design of reinforcement to avoid its ill effects (cracking of hardened concrete).

iii. Thermal Shrinkage.

This may be due to fall in temperature of concrete from the time it is laid till it sets completely.

Thus, when concrete laid at 30°C cools down to 15°-18°C, some shrinkage may be expected. It may be negligible on its own account.

But when added to drying shrinkage, it becomes necessary.

EXPANSION:

Concrete may expand on hardening due to the following two reasons:

Thermal Expansion: In massive concrete works, when the upper layers are laid before the lower layers have completely set, there can arise a phenomenon of thermal expansion in the lower layers.

This is because the heat of hydration gets accumulated in those layers and may attain magnitudes beyond acceptable limits.

Chemical Reactions: Alkali-aggregate reactions are known to cause a definite expansion in the concrete.

The reaction between amorphous silica of aggregates and oxides of potassium and sodium – from the cement used in aggregate yield crystalline structures of bigger volumes.

This change becomes harmful because these gel-structures are not as stable and strong as those formed by reaction between calcium oxide and silica.

They become the cause of cracking and quicker deterioration of hardened concrete.

Final Words:

So, These are some properties of hardened concrete. If you have any questions feel free to ask me in the below comment section.

Don’t forget to share it. Thanks!

Read More: How to Mix Concrete | Mixing Concrete by Hand and Machine.

Read More: Soundness of Cement & Its Test by Le Chatelier Apparatus.

Appreciating the hard work you put into youur website and

detailed information you present. It’s nice to come across a blg every once in a while tjat

isn’t the same unwanted rehashed information. Fantastic read!

I’ve bookmarked your site and I’m including your RSS feeds to my

Google account.

Thank you so much for the job we’ll done

I filled a crack in my existing concrete floor two days ago with fresh cement. I used the correct amount of water to cement ratio. When I left it to dry overnight it was smooth, now, 2 days later it is not. Is this due to water evaporation or non compatibility with the existing concrete floor?