Water Distribution System.

Extensive water distribution system is needed to deliver water to the individual consumer in the required quantity and under a satisfactory pressure.

This water distribution system is often the major investment of a municipal waterworks.

Types of Water Distribution System.

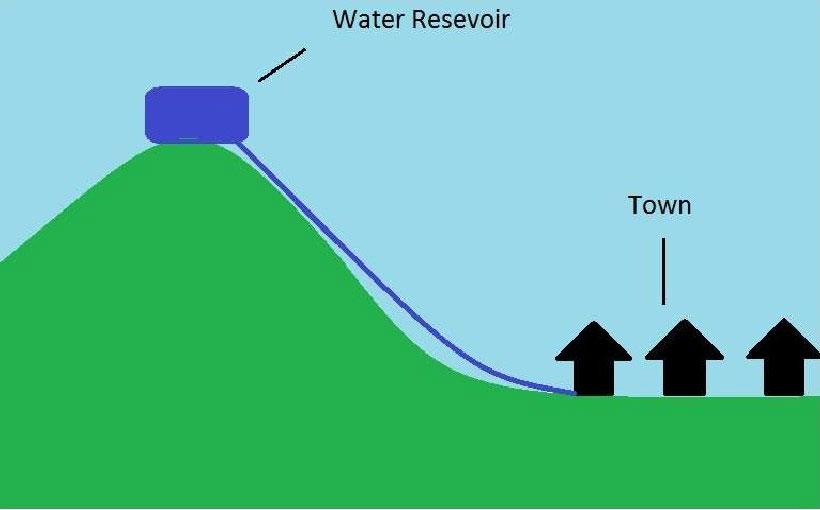

If topographic conditions are ideal, gravity distribution is used.

This requires a reservoir at a sufficient elevation above the city so that water can reach to any part of the distribution system with adequate pressure without pumping.

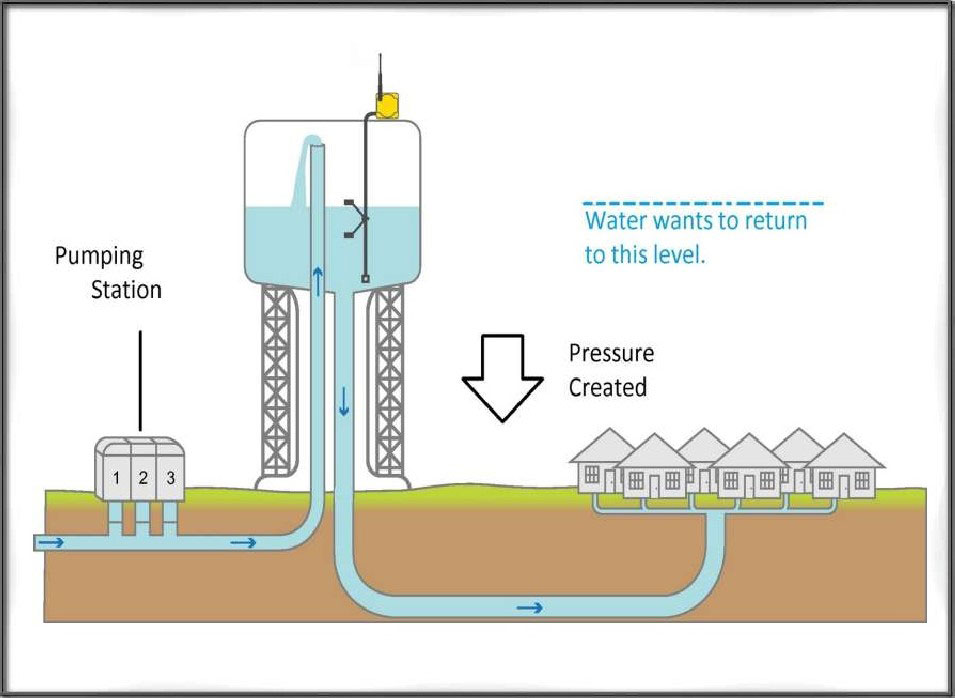

If pumping is necessary, water may be pumped directly into closed distribution lines, or it may be pumped into distribution reservoirs which serve to equalize pumping rates throughout the day and provide for peak use.

A tree-like water distribution system with many dead ends is unsatisfactory because water may become stagnant at the extremities of the system.

Moreover, if repairs are necessary, a large district must be cut off from the water.

Finally, with locally heavy demand, or during a fire, the head loss may be excessive unless the pipes are quite large.

A single-main system is one in which a single main serves both sides of a street.

In a double-main system, there is a main on each side of the street. One pipe supplies fire hydrants and domestic service on its side of the street.

While the other (and smaller) pipe serves only domestic needs on the other side.

The chief advantage of the two-main system is that repairs can be made without interfering with traffic and without damage to the pavement.

Pressure Requirements in Water Distribution Systems.

In designing water distribution systems, pressure requirements for ordinary use and fire fighting must be considered.

In residential districts, tire pressures of 60 psi at the hydrant are recommended.

In commercial districts, a minimum pressure of 75 psi is tolerable, but higher pressures must be provided in districts with tall buildings.

The American Water Works Association recommends a normal static pressure of 60 to 75 psi throughout a system.

Watch the Video Below for Better Understanding.

Many cities use fire-department motor pumpers to develop the necessary tire pressure so that normal operating pressure can be less than that quoted above.

The maintenance of high pressure in mains means increased pumping costs and usually also increased leakage.

Some large cities have installed dual systems in business districts, a low-pressure system for ordinary use and a high-pressure system (150 to 300 psi) for fire fighting only.

Other cities use standby pumps to raise the pressure in the entire system whenever a fire occurs.

Faucet pressures of 5 psi are satisfactory for most domestic needs.

Assuming a maximum pressure loss of 5 psi in the meter, about 20 psi in the house service pipe and plumbing, and with the main about 5 ft below ground level, a total pressure of about 35 psi in the main is adequate for residential districts with one and two-story houses.

Allowing about 5 psi for additional stories, a pressure of 75 psi should be satisfactory for buildings up to 10 stories in height.

Many cities require owners of tall buildings to install booster pumps in order to avoid the need for very high pressures in the mains.

Unnecessarily high pressures should be avoided since leakage loss in the mains and from leaky plumbing fixtures will be increased.

Distribution Reservoirs.

Distribution reservoirs are used to provide storage to meet fluctuations in use, to provide fire storage, and to stabilize pressures in the water distribution system.

The reservoir should be located as close to the center of use as possible.

The water level in the reservoir must be high enough to permit gravity flow at satisfactory pressures to the system which it serves.

In large cities, several distribution reservoirs may be located at strategic points throughout the city.

Water is usually pumped into a distribution reservoir when the demand is low and withdrawn by gravity flow during periods of high demand.

Elevated storage may be advantageously employed for pressure stabilization.

Various types of distribution reservoirs are built to meet the topographic and structural conditions encountered.

If hills of adequate elevation exist in or near the town, a surface reservoir, either below ground level or of the cut-and-fill type, is usually the best selection.

Small reservoirs may be simple excavations lined with gunite, asphalt, an asphalt membrane, or butyl rubber.

Larger reservoirs require a concrete lining, with side walls designed as retaining walls to resist external soil loads with reservoir empty.

Most surface reservoirs are covered to prevent contamination by animals, birds, and human beings, and, by shutting out sunlight, the growth of algae.

Reservoir roofs may be of wood, concrete, or steel. Pre-cast slabs of light weight concrete are widely used.

In at least one instance a reservoir roof has formed part of a city street. An open distribution reservoir should have a high fence around it to keep out trespassers.

If the topography does not permit sufficient head from a surface reservoir, a standpipe or elevated tank may be used to gain the necessary height.

Steel, reinforced concrete, and timber are used for the construction of standpipes.

Stand Pipes.

A steel standpipe is made of steel plates which are joined together by welding or riveting.

Pre-stressed construction is extensively used for concrete standpipes to minimize cracking. Pre-stressing is usually accomplished by wrapping the tank with a continuous wire, which is then covered with mortar.

Since large variations in pressure are undesirable in a distribution system, fluctuation of the water level in a stand pipe is usually limited to 30 ft or less.

Generally, standpipes over 50 ft high are not economical since the lower portion of the standpipe serves only to support the upper useful portion.

The economic limit of height for standpipes is reached when the supporting structure for an elevated tank becomes less costly than the lower ineffective portion of the standpipe.

There are many different types of elevated tanks.

The selection of type, number, and location of distribution reservoirs is an economic problem in which annual cost of reservoirs, pipe, and pumping should be minimized.

Surface reservoirs can be larger, and hence fewer might provide adequate storage.

However, if suitable surface sites are not favorably located in the distribution area, longer supply mains may be necessary.

In addition, larger mains may be required to keep pressures at proper levels.

Read More: Earth Dam: Types of Earthen Dam and its Construction.

Construction and Maintenance of Water Distribution System.

The basic requirements of pipes for water distribution system are adequate strength and maximum corrosion resistance.

Cast iron, cement-lined steel, plastic, and asbestos-cement compete in the small Sizes, while steel and reinforced concrete are competitive in the larger sizes.

In cold climates, pipes should be far enough below ground to prevent freezing in winter.

For even the coldest parts of the United States, a depth of 5 ft is generally more than adequate.

In warm climates, the pipes need to be buried only sufficiently to avoid damage from traffic loads.

Service connections to cast iron or asbestos cement pipe are made by tapping the distribution main with a special tapping machine which provides a threaded hole 1/2 to 2 inches in diameter.

A corporation cock is then installed with a flexible gooseneck pipe leading to the service pipe.

The gooseneck prevents damage if there is an unequal settlement between the main and the service pipe.

Service pipes leading from the main to the consumer are usually copper tubing or galvanized steel.

For single-family dwellings, 3/4 to 1-1/4-inches pipe is common for service pipes, but larger sizes may be needed for apartment houses or business establishments.

When a new pipe is first filled, all hydrants and valves are opened so that air can escape freely.

The filling is done slowly and may require several days for large systems. Excessive pressures can develop if the air is not properly driven out of the system.

When a steady, uninterrupted stream issues from a hydrant, it is closed. The procedure is continued until all valves, and hydrants are closed and the system is full of water.

Leakage in Water Distribution System.

Leakage from distribution systems will vary with the care exercised in construction and the age and condition of the system.

Construction contracts usually specify an allowable leakage in the range from 50 to 250 gpd (gallon per day) per inch of pipe diameter per mile of pipe.

The test is made by closing off a length of pipe between valves, and all service connections to the pipe.

Water is introduced through a special inlet, and normal working pressure is maintained for at least 12 hours while leakage is measured.

In an operating system, the total loss is estimated from the difference between the measured input to the system and metered deliveries to the customers.

There are several possible methods of locating a specific leak. Patented leak detectors use audio phones to pick up the sound of escaping water or the disturbance in an electrical held caused by saturated ground near the leak.

Watch the Video Below for Better Understanding.

Similar devices may be used to locate the pipe itself if the exact location is unknown.

If pressure gauges are installed along a given length of pipe from which there are no take-offs, a change in slope of the hydraulic gradient will indicate a leak.

In some instances, the escaping water itself or unusually lush vegetation may show the location of a leak.

If the leak is due to a faulty joint, it may be necessary only to repack and re-caulk the joint.

If the pipe itself is cracked, the entire length of pipe may have to be replaced.

The location of all pipes, valves, and appurtenances should be entered on maps. This information is essential in case repairs are required at a future date.

Disinfection of Distribution System.

While the pipe is being handled and placed, there are many opportunities for pollution. Hence, it is necessary to disinfect a new system or an existing system after repairs or additions.

Disinfection is usually accomplished by introducing chlorine, calcium hypochlorite, or chlorinated lime in amounts sufficient to give an immediate chlorine residue of 50 mg/l.

Watch the Video Below for Better Understanding.

The chemical is introduced slowly and permitted to remain in the system for at least 12 and preferably 24 hours before it is flushed out.

The flushing may be accomplished by opening several fire hydrants.

The hydraulic efficiency of pipes will diminish with time because of tuberculation, incrustation, and sediment deposits.

Flushing will dislodge some of the foreign matter, but to clean a pipe effectively, a scraper must be run through it.

The scraper may be forced through by water pressure or pulled through with a cable. Cleaning, even though costly, may pay off with increased hydraulic efficiency and increased pressures throughout the system.

The effects of cleaning may last only a short time, and in many cases, the pipes are lined with cement mortar after cleaning to obtain more permanent results.

Read More: What is Gravity Dam and its Construction?

Thanks for Reading Don’t Forget to Share it.

Thank u

thanks a lot

gREAT JOB

Great explanation of the Water Distribution Systems.

GOOD

Thank you for some other magnificent post. The place else

may anybody get that type of information in such a perfect way of writing?

I have a presentation subsequent week, and I am on the look for such

information.

Please, how can I get any PDF related to (Design of water distribution network)

I wanted to use it for my final year project (HND ii) in the school,

I will be very happy if someone can help me out

nice information